Our Services

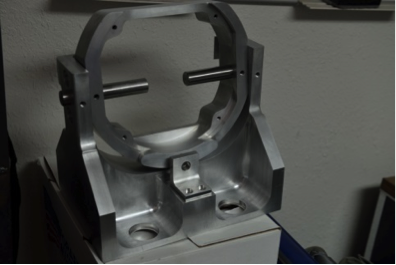

BOSS Inc. maintains a prototype machining, manufacturing, and assembly shop floor. BOSS Inc. complements its suite of tools and equipment with a CNC Lathe and a 4 axis mill. Equipment is certified each year to ensure that we deliver a high quality product.

BOSS Precision will take your part or assembly from initial prototype to small volume production. We work in both public and private sectors of industry, with corporations, government entities, and individuals. We can assist in early product development (if in-depth development support is required we work closely with our “sister” company Capstan Technologies).

We offer precision machining, manufacturing, and mechanical assembly services. We also specialize in custom prototype projects. Some of our work has been for the R&D sector with a focus on prototype development. BOSS Precision contributed to the Army’s EM Gun program, the Hobby-Eberly Telescope for the McDonald Observatory in Fort Davis, TX, superconducting motors for The University of Texas at Austin, energetic materials projectiles for EMPI in Austin, TX and the Alternative Energy and Biofuels Program led by The Center for Electro Mechanics, University of Texas Austin.

Machining and Manufacturing Services at a Glance

- CAD/CAM Services

- Pro-E Wildfire

- SolidWorks

- Pro-NC

- Precision CNC milling & turning operations

- Reverse Engineering and design support

- Prototype design and fabrication

- Small volume production and assembly

- CMM Inspection

- Engraving

- Standard welding processes associated with machining/fabrication project

- Sawing

Independent Consulting Services

- Materials selection

- Engineering Project Management

- End to End Quality Management covering areas such as electronic technology roadmap development, Quality Management System Review and Assessment, Quality and Reliability of components and subassemblies, Problem Resolution, etc.

- Electronic component “part information” management (covering areas such as part lifecycle, part reuse, part risk, etc.,)